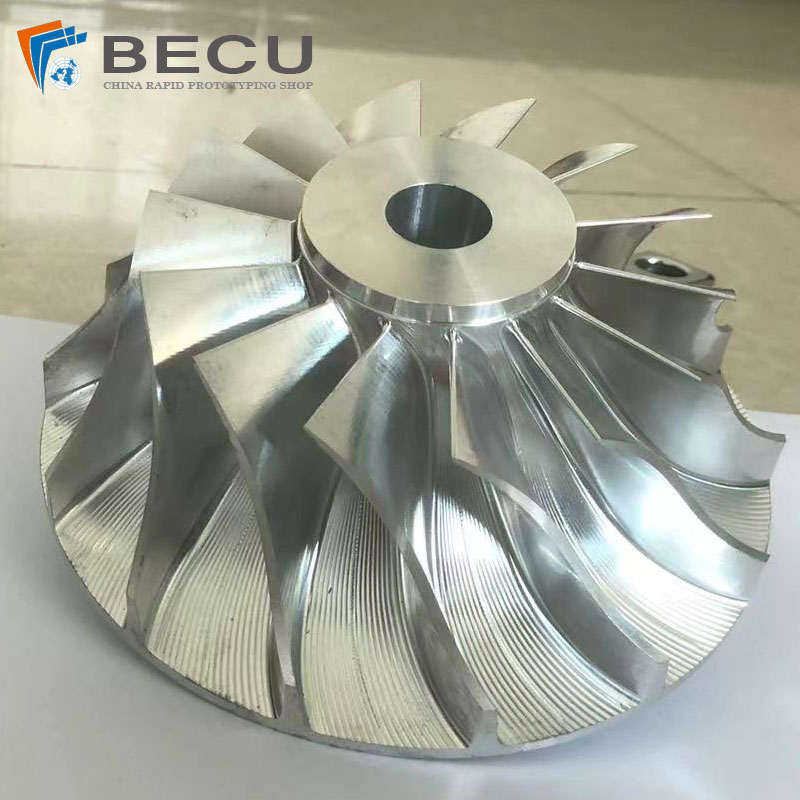

In the continuously developing world of liquid mechanics, the integration of precision machining is set to change impeller performance. By utilizing these innovative technologies, engineers can create impellers with incredible accuracy, allowing for optimal fluid flow efficiency. This augmented ability to manipulate shapes at a micro level will profoundly affect various sectors.The continuously developing world of hydrodynamics, we see the integration of precision machining is set to revolutionize impeller performance. Through the use of these innovative machining processes, engineers can create impellers with outstanding accuracy, allowing for optimal fluid flow efficiency. This enhanced ability to manipulate shapes at a micro level will significantly affect various industries.Ultimately, embracing CNC in impeller manufacturing not only enhances operational efficiency but also opens up opportunities for innovation. With improved design possibilities and the ability to push the boundaries of what’s possible, manufacturers can explore new markets and applications. This strategic advantage can lead to a significant return on investment, ensuring that organizations remain at the forefront of their industries.

7 Questions You Need To Ask About Cnc Prototyping

Computer Numerical Control prototyping has become crucial in transforming conceptual ideas into tangible designs, particularly with efficient impellers. This technology allows engineers and designers to rapidly create precise prototypes that can be tested for efficacy. By using CAD, they can visualize their dreams, making it easier to modify parameters before committing to a full-scale production run, ultimately saving time and resources.CNC prototyping has become crucial in transforming theoretical ideas into tangible designs, particularly with efficient impellers. Such technology allows engineers and designers to rapidly create precise prototypes that can be tested for performance. By using CAD, they can visualize their dreams, making it easier to refine parameters before committing to a full-scale production run, ultimately saving time and resources.

Moving forward, partnerships between experts in fluid dynamics, software developers, and manufacturers will be vital in driving innovation. By pooling together knowledge and resources, these professionals can push the boundaries of what is possible in the realm of impeller design. This teamwork will foster creative solutions that tackle current challenges while anticipating future demands within the sectors related to fluid dynamics, ultimately resulting us toward a new era of engineered excellence.Moving forward, partnerships between experts in fluid dynamics, software developers, and manufacturers will be vital in driving progress. By pooling together knowledge and resources, these professionals can push the boundaries of what is possible in the realm of impeller design. This teamwork will foster creative solutions that tackle current challenges while anticipating future demands within the sectors related to fluid dynamics, ultimately leading us toward a new era of engineered excellence.

The Philosophy Of Impeller Machining

Additionally, with 3D printing increasingly being integrated into CNC processes, the future of impeller fabrication looks promising. This convergence of technologies allows for the production of advanced geometries, which were once unachievable through conventional means. These disruptive designs can enhance the turbulence and promote better mixing, leading to enhanced system performance, energy savings, and reduced operational costs.Additionally, with additive manufacturing increasingly being integrated into CNC processes, the future of impeller fabrication looks promising. This convergence of technologies allows for the production of complex geometries, which were once unachievable through conventional means. These innovative designs can enhance the turbulence and promote better mixing, leading to enhanced system performance, energy savings, and reduced operational costs.

The role of testing cannot be understated; once the prototype is created, it undergoes extensive evaluations to ensure it meets functional standards. These tests often include hydraulic analysis and stress testing to assess how well the impeller will perform in real-world scenarios. The insights gained during this stage are crucial as they often lead to cyclical improvements and necessary adjustments, enhancing both the design and its future iterations.The role of testing cannot be understated; once the model is created, it undergoes extensive evaluations to ensure it meets performance standards. These tests often include flow analysis and stress testing to assess how well the impeller will perform in real-world scenarios. The insights gained during this stage are crucial as they often lead to cyclical improvements and necessary adjustments, enhancing both the design and its future iterations.

In addition, the versatility of CNC machining systems allows manufacturers to easily adjust production parameters for different impeller designs without extensive impeller][img]www.ultirapid.com/cnc-machining/cnc-prototype-machining/">impeller[/img][/url]Quelle: https://be-cu.com machining retooling. This makes it feasible to innovate and bring new products to market much faster than traditional approaches would allow. Therefore, as trends evolve, CNC technology prepares firms to be responsive and adaptable in a competitive landscape.In addition, the flexibility of CNC machining systems allows manufacturers to readily adjust production parameters for different impeller designs without extensive retooling. This makes it feasible to innovate and bring new products to market much faster than traditional approaches would allow. Therefore, as trends evolve, automated solutions prepares firms to be responsive and adaptable in a competitive landscape.Rotors are critical components in various industries, making high-quality manufacturing essential. The ability to utilize CNC machining allows for the creation of intricate designs and detailed geometries that meet specific engineering requirements. As a result, products not only perform better but also go beyond client expectations, leading to increased customer satisfaction and loyalty.

©2025